Technological components, distillery, tanks, boilers...

Tailor-made stainless steel containers

Bulk storage tanks and storage silos

PACOVSKÉ STROJÍRNY manufacture large-volume storage silos and stainless steel tanks for bulk substances and liquids. They are designed for storage of food products, non-food plastic granules or building materials or possibly for liquids such as water, oils, alcohol or molasses.

In addition to production, our professional team also creates project documentation, handles installation, assembly and transport of oversized goods.

Water heaters and storage vessels

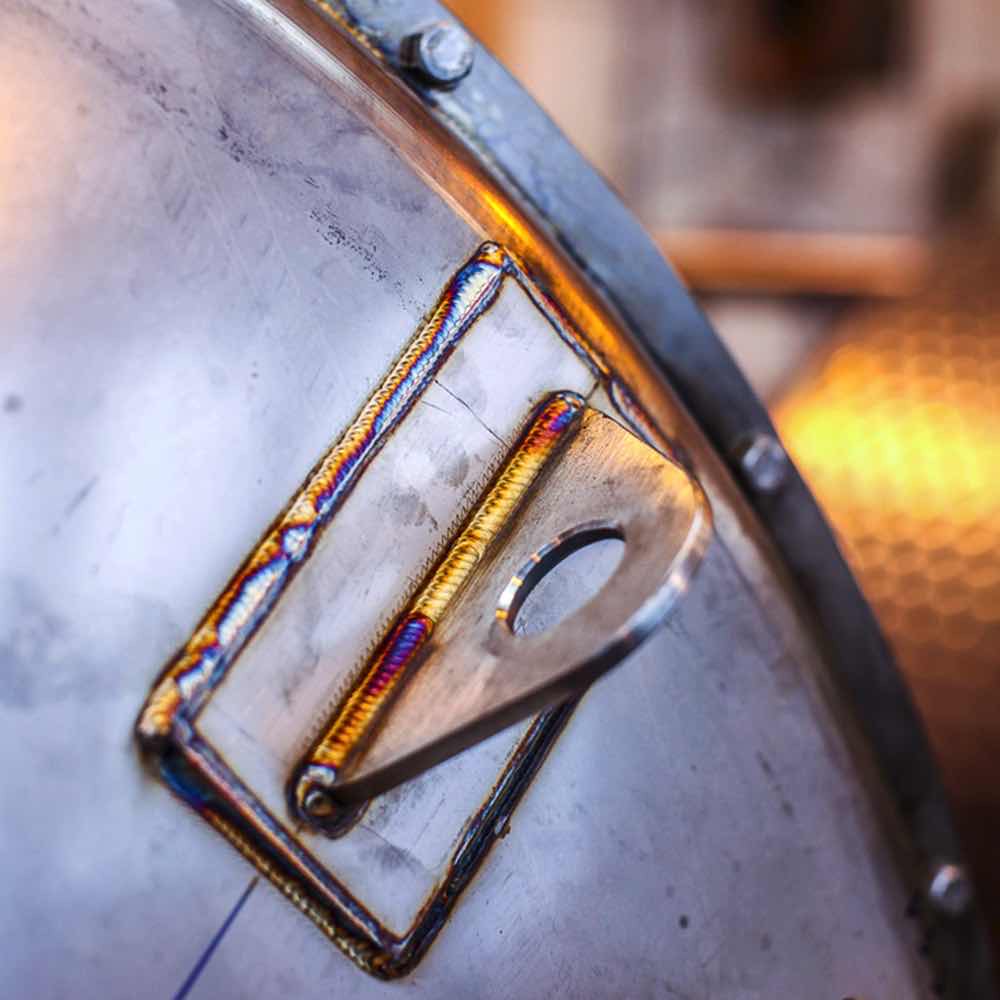

Water heaters and storage vessels made from stainless steel are used to store and accumulate warm drinking or heating/service water used in residential or industrial distribution systems. The basic series offer the following volumes: 300, 500, 750 and 1,000 litres. The operational pressure in accumulation vessels reaches 10 bar (1 MPa) and the operational temperature is 95°C. Vessels are equipped with standard necks. Additional equipment depends on individual orders and the planned type of use.

Accumulation vessel may be fitted with a water heater. The water or medium may be heated by means of plate or heat exchangers, or possibly with electric heating elements. Delivered with a control system. The surface of the vessel is chemically treated by staining and passivation for stainless surfaces, which provides long service life. Proper seal of accumulation vessels is guaranteed for at least five years.

TECHNOLOGICAL PROCESS UNITS

Complete supply of technological process units for the food and chemical industries.

Fermentation driers – process lines for blood drying for the production of bovine hemoderivative.

Operating units for high-capacity filter systems for industrial wastewater.

Ammonia stripping tanks.

Stainless steel tanks for pumping stations.

Evaporation stations for solvent recovery.

Large capacity tanks built on site.

STORAGE TANKS AND SILOS

Capacity of silos from 10 m3 up to 200 m3.

Capacity of storage silos up to 4 000 m3.

Bulk storage silos and stainless steel vessels for loose materials and liquids designed for storing food products, non-food plastic granules, building material, and liquid media.

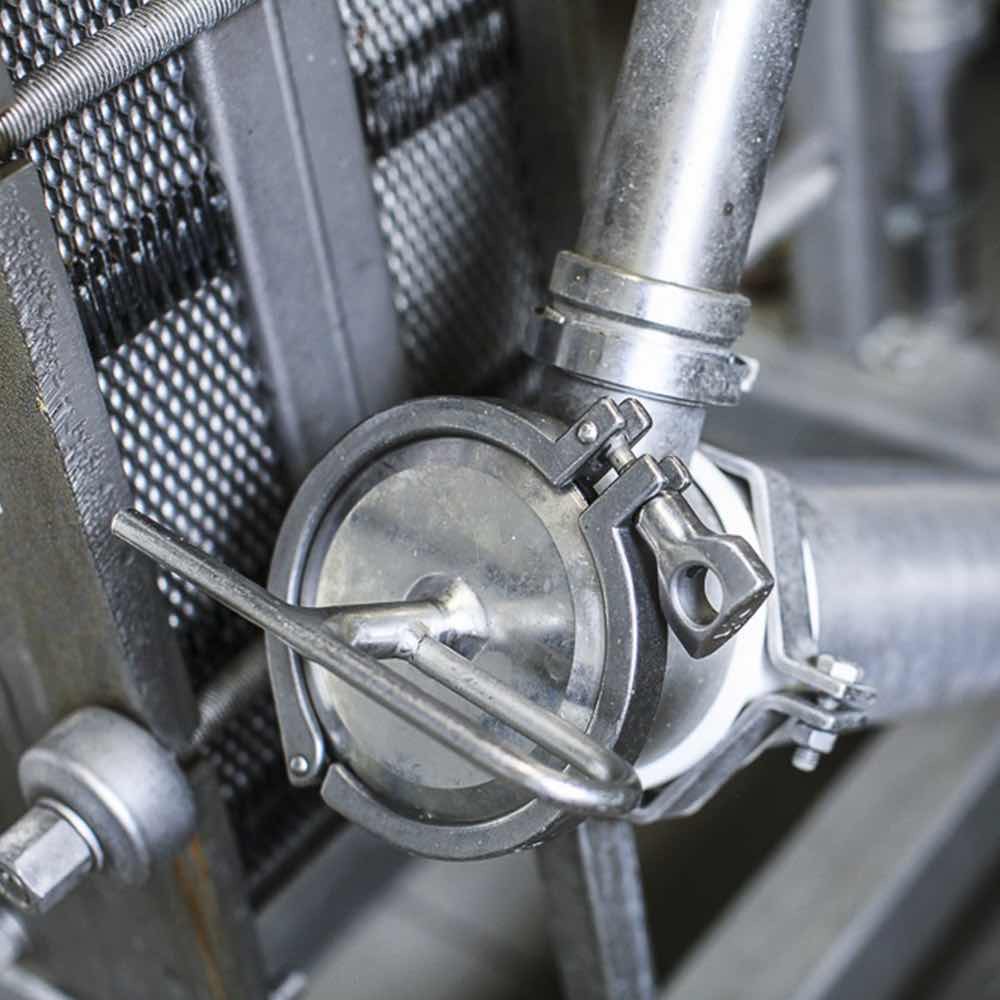

INDUSTRIAL DISTILLERIES

Distillation, storage and fermenting units.

Column apparatuses made of stainless steel or copper.

Complete distilling units for the production of alcohol.

Equipment for the preparation and storage of raw materials, auxiliary materials and the finished product.

Quotation preparation based on the specifications of raw materials, expected volume of alcohol produced, its quality and intended use, and other specific requirements.

FRUIT DISTILLERIES and SMALL GROWER DISTILLERIES

Small grower and fruit distilleries for processing fruit and grape mash to make fine spirits.

Stainless steel or copper products.

The unique product made with the use of modern technology retains all the desirable qualities of processed fruit and other ingredients.

Our products

- Milk storage tanks

- Cooling tanks

- Storage silos

- Mobile device

- Fruit distilleries

- Small grower distilleries

- Technological units

- Accumulation containers

- Additional devices